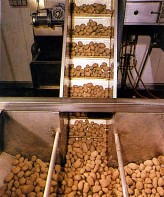

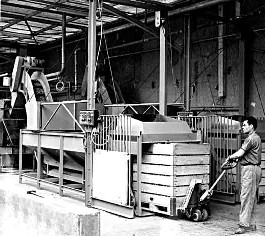

Photo 1-4: Crate tipping device with bin below. Tubers / root vegetables are removed via the adjustable conveyor belt. Storage bin and belt function as a dosing bin.

Other types of storage bins, custom-made according to your request, are available within our product range.