Düsseldorf . Deutschland

The Continuous Universal-Multi Disc Peeling Machines (MSS)

as Carborundum Peeling Machines

Series AK, BK and CK

CARBORUNDUM PEELING WITHOUT WASTE WATER

(The carborundum discs can be replaced partly or

completely with blade peeling discs)

Design:

Arrangement of many small carborundum peeling discs on

horizontal, extendable peeling units with a conveying device

moving over the peeling area.

The

machines can be supplied with one peeling unit (AK), with 2

peeling units (BK) or with 3 peeling units (CK). Each

peeling unit is provided with 24 peeling discs.

(K

= Carborundum model).

The

newly-designed machine can be used for the continuous

carborundum peeling of potatoes, several different tubers

and root vegetables as well as fruit.

The

feeding of raw material into the machine must be carried out

regularly and adjustably. The products to be peeled are

passed, by means of a conveying device, over many small

carborundum discs.

It

is especially worth mentioning that the products are peeled

in a careful and gentle way, which results in a better

keeping quality and durability, e.g. in case of peeled

potatoes.

The

peeling units, on which the small carborundum discs are

mounted, can be easily pulled out of the machine. Thus, the

peeling discs can be cleaned or exchanged.

The

speeds (number of revolutions) of the peeling discs and the

conveying device can be electronically adjusted, infinitely

variable and independent of each other. A switch box does

belong to the delivery.

If

the discs are provided with a fine carborundum granulation,

one will achieve a very smooth and accurate peeling result.

Please see pictures of this peeled potatoes on the web.

By

means of an additional equipment, the machines can work

without producing waste water, when peeling most of the

products. Please see picture of peeled potatoes on our

Internet presence.

Capacities (in-feed, approx.)

|

|

Machines

|

AK |

BK |

CK |

|

1. |

for

potatoes pre-peeled with carborundum (at 90 per cent),

e.g. in roller peeling machines |

1.000

kg/h |

2.000

kg/h |

3.000

kg/h |

|

2. |

Capacities

(approximate in-feed) of raw goods |

500 kg/h |

1.000

kg/h |

1.500

kg/h |

The

power ratings are only guidance levels. The quality of the

raw goods, the size of the potatoes, the required level of

cleanness and other factors effect the capacity and can

cause big variations of capacity.

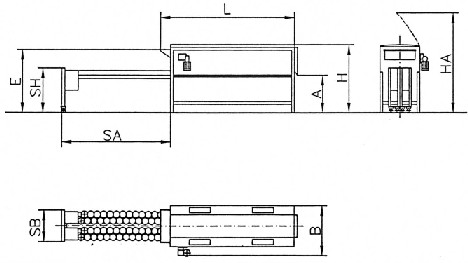

Dimensions

and further technical data: (without

additional equipment for peeling without producing waste

water, approx.):

AK

BK

CK

Length

L

3100

3100

3100

Height

H

1500

1500

1430

Width

B 780

1105

1430

Extended

length

of peeling unit

SA

2450

2450

2450

Width of peeling unit

SB 321

646

971

Height of peeling unit

SH 992

992

992

Height

of opened

machine

HA

2200

2200

2200

Discharge height

A 830

830

830

Input height

E

1392

1392

1392

3 / N / PE / 400 V / 50 Hz

1,7 kw

3,2 kw

4,7 kw

Minimum pressure:

1

bar

1 bar

1 bar

Water supply:

R ½”

R ½”

R ½”

For peeling without waste water, the machines and their

movable peeling units are normally put somewhat higher in

order to get floor space for the installation of a worm

conveyor (auger) and a pump or for a conveying machine for

the removal of skins.

Conversion

(retooling) into blade peeling machines or into carborundum

/ blade peeling machines

The

machines can easily be retooled into blade peeling machines

by replacing the carborundum discs with blade peeling discs.

(Denomination

of types: AM, BM and CM)

Moreover,

it is possible to retool the machines quickly into combined

carborundum/blade peeling machines.

(Denomination

of types: AKM, BKM and CKM)

Special

Features:

1.

The carborundum discs can be supplied with rough

granulation down to finest carborundum coating.

2.

If a fine granulation is applied, e.g. potatoes leave

the machine with a very smooth surface. The peeled products are very much liked for

their excellent appearance. (Pictures on the web)

3.

The soft peeling process also allows the peeling of certain sorts of

fruit and other sensitive (fruit products).

4.

It is especially worth mentioning that the machines

can work without

producing waste water, if provided with an additional

equipment, when peeling most of the products.

Test machine (= laboratory machine near to reality)

As

a rule, we have a machine for test purposes at our disposal,

equipped with a large variety of peeling discs (also blade

peeling discs). Please

ask us for more details as far as the carrying out of tests

is concerned. – Read also our paper Q

155: “Peeling

Tests with a Multi-Disc Peeling Machine MSS”.

Pictures of the machines: on the web!

This

paper contains non-committal notes. We do not lay claim to

completeness. Alterations reserved.

Our order confirmation, accepted by our customers, is in

effect upon delivery. The presentation of a new edition of this treatise will

substitute for any previous versions.

Copyright

by DORNOW food technology GmbH, D-40549 Düsseldorf

DORNOW total on the Web: www.dornow.de

Q131 E4

Dornow food technology GmbH,

Willstätterstr. 12,

D-40549 Düsseldorf - Germany, USt-Id.-Nr. DE119264470

Tel. ++49-211-527060, Mobile ++49-172-2614932,

Fax ++49-211-596883, email office@dornow.de,

Internet: www.dornow.de,

Commerzbank

AG, Konto-No. 1452333, BLZ 300 400 00, Managing Director Karl-Dietrich

Dornow, Amtsgericht Düsseldorf, HRB 22597