Düsseldorf . Deutschland

The

Large Fryers with basket inserts (bins) that can be lifted,

moved and emptied (6400, 6401)

for the production of potato chips (UK: crisps), pellet

products, pre-fried French fries (UK: chips),

onions and other fried products

Denominations and types of fryers:

"Industry

301" (2 frying vats, Art.-No. 6400) and "Industry

151" (1 frying vat, Art.-No. 6401).

Heating by means of gas (propane, natural gas or town gas),

"Industry 301":

100 kWh,

"Industry 151":

50 kWh.

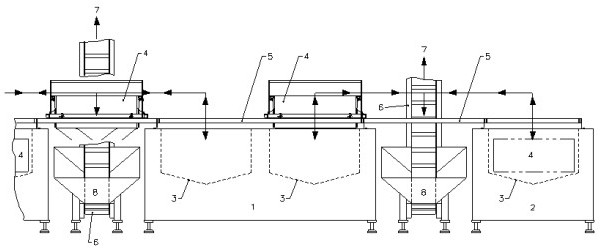

Positions of basket inserts (bins)

(see

drawing):

| Position

I: |

The basket insert (4) is in the frying vat (3) together with the goods to be fried (filling of the vat by hand or by means of conveyor belt). |

| Position

II: |

The basket insert (bin) is lifted from the vat after the termination of the frying time by means of a lever, actuated by an operator, to be then put on rails above the frying vat (5). |

| Position

III: |

The basket insert (bin) is pushed by the operator over the rails, until it gets into a position above the feeding funnel (8) of a conveyor belt (6). Here the basket insert (bin) opens automatically. The fried products drop into the feeding funnel and are moved on by the conveyor belt. |

After emptying the basket insert (bin) is moved back into

the frying vat, and the whole process starts again.

One operator is required.

He / she can operate one to four frying vats,

according to the required frying times (pellets have a very

short frying time, i.e. one person operates one frying vat.

Due to the short frying time, the throughput capacity of the

one frying vat for the production of pellet products is

correspondingly high).

The

basket inserts (bins) constructed like that facilitate the

work of the operators.

The end of one frying time (frying period) is indicated to

the personnel by sound signals and /or light signals.

Representation of a line with the Large Fryers "Industry

301" and "-151"

|

1. |

Large

Fryer "Industry 301", (Art.-No. 6400) |

5. |

Rails |

|

2. |

Large

Fryer "Industry 151", (Art.-No. 6401) |

6. |

Conveyor

belt |

|

3. |

Frying

basin / Frying vat |

7. |

To

the cooling belt / cooling tunnel |

|

4. |

Frying

basket (frying bin) |

8. |

Feeding

funnel |

More detailed specialised

literature: on the Web (dornow.de), see section

B, subsection 4 - “Chips (UK: Crisps) Production Lines”

and subsection 3 - “French fries (UK: Chips)

Production Lines”.

This

paper contains non-committal notes. We do not lay claim to

completeness. Alterations reserved.

Our order confirmation, accepted by our customers, is in

effect upon delivery. The presentation of a new edition of this treatise will

substitute for any previous versions.

Copyright

by DORNOW food technology GmbH, D-40549 Düsseldorf

DORNOW total on the Web: www.dornow.de / www.dornow.com

Q161 E1

Dornow food technology GmbH,

Willstätterstr. 12,

D-40549 Düsseldorf - Germany, USt-Id.-Nr. DE119264470

Tel. ++49-211-527060, Mobile ++49-172-2614932,

Fax ++49-211-596883, email office@dornow.de,

Internet: www.dornow.de,

Commerzbank

AG, Konto-No. 1452333, BLZ 300 400 00, Managing Director Karl-Dietrich

Dornow, Amtsgericht Düsseldorf, HRB 22597