7. Our Shop and Our Mechanics are There for you!

Services:

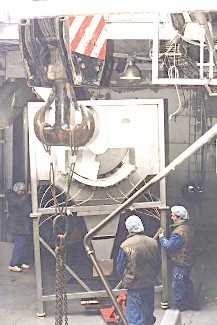

| I. | Assembly of machines purchased from us and the instruction of your engineering staff | |||||||||

Our technicians are skilful in putting your machines purchased from us into operation. Moreover, they are ready to instruct your technical personnel at request. This can be done on your premises or in our warehouse before the delivery of the machine/plant.

|

||||||||||

| II. | Service and Repair | |||||||||

Generally, our machines can be serviced by our customers (see I). Nevertheless, after several years it may be advisable to have a machine checked by a specialist. Our mechanics will service it thoroughly ! We are also pleased to handle those repairs you prefer not to do yourself for you. Either on your premises or in our workshop ! |

||||||||||

| III. | ||||||||||

There is a specific department in our workshop, which deals with the re-coating of carborundum discs, carborundum side walls, or carborundum rollers with granulated carborundum. The old coating is usually removed first. If you prefer to do the job yourself, we can also supply you with granulate and chemicals. Also, it is possible to learn how to carry out the re-coating process from our mechanics, enabling you to do the job in the future. |

||||||||||

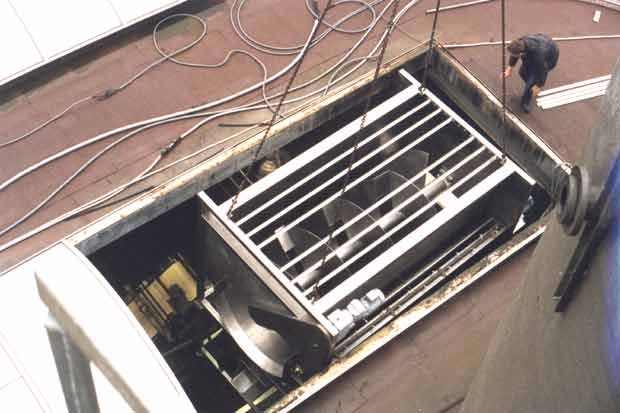

| IV. |

Special Requests, Relocation, etc. |

|||||||||

|

Please do not hesitate to ask for further services our technicians could take over for you.

|

||||||||||

1

1 2

2