| G. - 9. |

Inspection Belts, Tables and Sorting Devices for Wet Areas |

|

|

for tubers, root vegetables, etc., and partially suitable for vegetables and fruit |

||

| 9.1 |

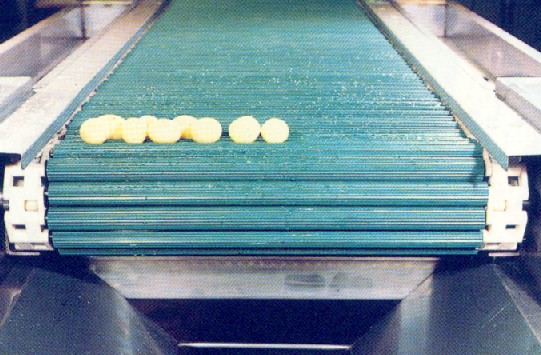

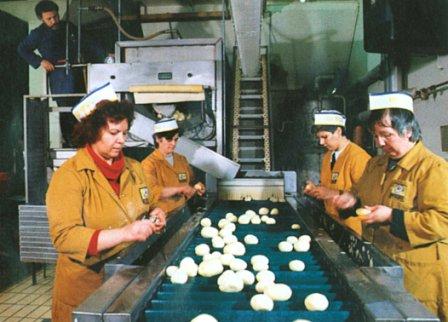

Roller Inspection Tables (Item no. 0200 ff., 0224 ff., 0248) |

|

1 |

2 |

|

| Because produce is constantly turned under the eyes of the staff, blemished spots are easily detected on DORNOW roller inspection belts. Blemished tubers/root vegetables are generally returned to the machine for a second peeling. | Roller

inspection belt

with a conveyor belt for produce that have to be re-peeled underneath it on the platform. |

|

3

3 |

4

4 |

|

5

5 |

6

6 |

|

7

7 |

||

| Roller inspection belt (special design) with plastic rollers of a very small diameter for small potatoes, baby carrots, small onions. All parts are plastic or other rustfree materials (except engine). | Rollers with

plastic bearings, available in various lengths. |

|

9

9 |

10

10 |

|

11

11 |

||

| A narrow roller inspection belt in connection with a MSS-A universal peeling machine. | Roller inspection belt with peeled yam (sweet potato). | |

14

14 |

||

| Roller inspection belt with peeled butternut. | Roller inspection belt with chanels. | |

| DORNOW

plastic chains are assembled from various links in our

workshop. |

Here you can see DORNOW plastic chains for our roller inspection benches. The highest quality guarantees the longest service life. | |

Suggestions for further reading:

| - Q66 |

Roller

inspection belts for peeled tubers and root

vegetables |

|

- Q94 |

Manual

post-treatment peeling or re-peeling of

mechanically-peeled potatoes for the catering sector ? |

|

-

Q129

|

The labor-saving combination of inspection table / potato dividing machine for smaller and midium-sized potato peeling facilities |

|

- Q152 |

Fast and slow-working personnel at the inspection table and in other critical areas of a commercial potato peeling facility. |