|

A.

- 1.

|

peeling

machines

|

| |

|

| |

|

|

1.1

|

Roller

peeling machines, R-OW series

Original

DORNOW construction |

| |

Peeling

roller diameter approx. 150 mm |

| |

|

| |

Please also

see section A.-1.32 -

peeling roller diameter approx. 100 mm |

| |

Available in the following

sizes: length of the rollers from 2000 up to 4000 mm,

diameter

of the screw conveyor from 500 up to 2500 mm |

| |

|

| |

Standard peeling without waste water |

| |

|

| |

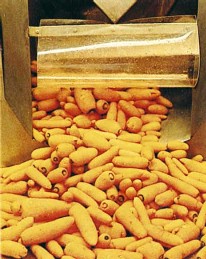

Continous, mechanical peeling of potatoes, carrots, beetroots (red beets)

(boiled and unboiled), onions, root celery (celeriac), cassava, manioc,

tapioca, oranges and pineapples (partially frozen) and other tubers,

root vegetables and fruits (0151 ff., 0160, 8050 ff., 8265ff., 9700ff.)

The machines are suitable for cleaning of root vegetables and tubers,

i.e. sugar beets for the production of fermentation gas without waste water

(see section E.-20.3)

|

1.1 |

|

|

1.2 |

|

|

A

DORNOW roller peeling machine R-OW-150-A for peeling of yuca fruit

(like cassava, manioc) ready for shipment to South America (diameter of

inside screw conveyor 1500 mm, larger machines available!)

|

|

|

|

1

|

|

2

|

|

3

|

|

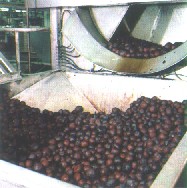

Cassava peeling during mounting in the Democratic Republic

of Congo (first day of

production)

|

|

Large roller peeling machine R-OW-190-A1 in a potato processing factory |

|

Large roller peeling machine R-OW-190-A1 for the peeling of tubers and root vegetable prior to

shipment |

3.1 |

|

4 |

|

5 |

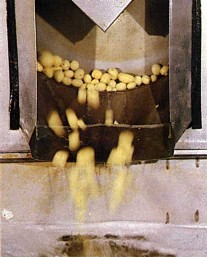

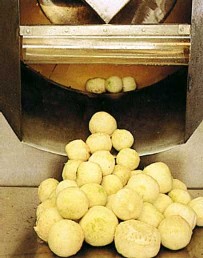

Roller

peeling machine R-OW-130-A in

action: potato peeling |

|

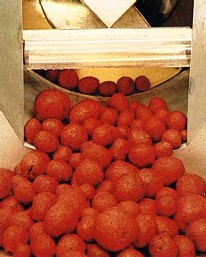

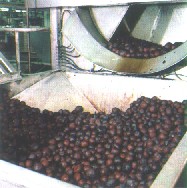

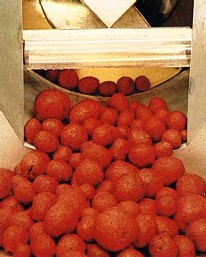

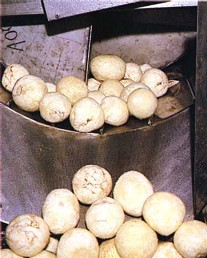

Beet roots,

peeled.

|

|

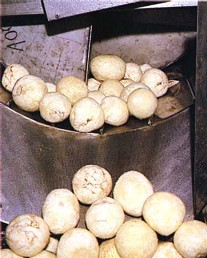

Root celery

(celeriac), peeled.

|

6

6 |

|

7 |

|

8 |

|

Largest roller peeling machine ever

built,

type R-OW-190-A1(mechanical working),

peeling rollers 4000 mm long, diameter of the inside

conveyor screw 1900 mm! (Art.-no. 8272). Recently this

machine was installed as integral part

in a steam peeling plant. Within the complete peeling

plant it has a regulative function and makes sure - even

with bad raw material - that the peeling result is constant

throughout the whole year .

|

|

Roller peeling

machine R-OW-60-A |

71Largest

9

9

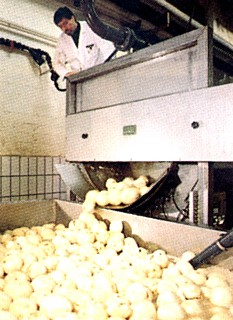

Big roller peeling machine R-OW-150-A1 in an onion processing factory for the production of roasted

onions.

- Diameter of the installed two screw conveyors inside 1500 mm, length of the peeling rollers 4000 mm

Further photos of the machines

series R-OW:

9.1 |

|

9.2 |

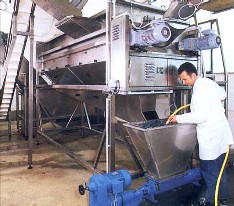

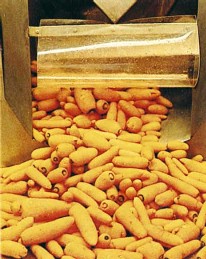

Two large roller peeling machines,

type

R-OW-150-A, interior diameter of the auger

1500 mm, delivered to a carrot juice factory. |

|

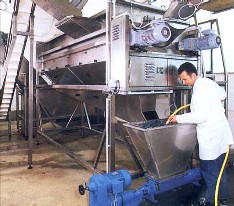

Potato waste peel, without the addition of

water,

flows into the collecting container of

a pump. |

10

10 |

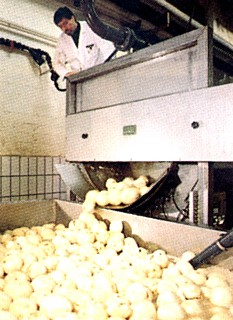

| In the background

the output of the DORNOW roller peeling machine R-OW-60-A is

visible, on the left hand the landing with staircase, which

leads to the peeling machine. - The potatoes, which can be

seen in the peeling plant, fall immediately into the DORNOW

storage bin. It has three functions: storing, washing and

dosing. |

11

11 |

DORNOW roller

peeling machine R-OW-110 with storage bin for underwater storage in a

company for ready-to-serve meals.

|

DORNOW is the world's leading manufacturer of

roller peeling machines with more than 30 years of experience in this area. Continuous

development guarantees that peeling machines and systems designed and

supplied by us now count among the most modern and largest around the

world, from raw produce reception down to the packaging of the peeled /

cut product. Optimum peeling results, reduced personnel and the saving of

water / waste water can be achieved. |

| |

|

|

| |

|

|

12

12

|

|

|

Uniform

peeling of any produce from all sides.

Shown here:

Root celery (celeriac), potatoes, boiled beet roots (red beets).

Further photos of peeled products: please see "Peeled

products".

|

13

13 |

|

| |

|

|

Roller peeling

machine R-OW-150-A,

interior diameter 1500 mm, in a commercial

potato peeling plant.

|

|

14 |

15 |

|

|

16

|

|

17

|

| Cassava

peeling in Africa with roller

peeling machine R-OW-130-A |

|

Roller

peeling machine R-OW-190-A1, length of peeling rollers

4 m |

18

18

Roller peeling

machine R-OW-130-A

-

|

Capacities of the

aforementioned machines: from approx. 0.5

- 25 t of raw produce/h. Inner spaces (screw conveyor diameter)

from 500 - 2500 mm.

|

|

| - |

Length of the

peeling rollers from 1000 - 4000 mm!

|

-

|

Degree of peeling of

the final product adjustable from gentle to aggressive.

Coating of peeling rollers according to your requirements,

also in gradations. Micro-fine grain peeling possible.

Result:"smooth as glass."

|

-

|

Normally no more waste water costs! No waste

water! Machines normally operate entirely without water. Any skins or

peel still attached to the peeled produce are separated in the attached

storage container with "washing unit." - In the case of "sticky"

produce or produce with awkward skin (i.e. onions, etc.) or other

difficult peel, water must be

added when required !

|

-

|

Machines are designed to be virtually

maintenance free. Strong axles, few moving parts. Bearings have dual

protection against moisture and dirt, when mounted

at a distance from wet areas. Few replacements of parts required. Sturdy

construction: 24-hour operation possible. Machines are extremely

durable.

|

-

|

Exchange or

recoating of peeling rollers can be easily

carried out by anyone. Devices for a quick exchange of peeling rollers

provided in almost all roller peeling machines.

|

|

|

19 |

|

20 |

|

21 |

|

22 |

|

23 |

potatoes

|

|

Beetroots, boiled and

unboiled |

|

Root celery

(celeriac) |

|

Carrots

|

|

Kohlrabi

|

|

24

|

|

24.1

|

|

24.2

|

|

24.3

|

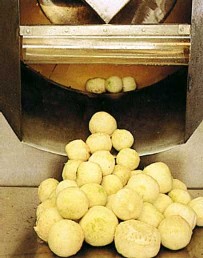

| DORNOW roller

peeling machines also peel many varieties of tropical fruit,

as shown here, manioc (cassava, tapioca) in Africa. A cleaner

result is achievable when fruit to be peeled is left in the

machine for a greater extent of time.

|

|

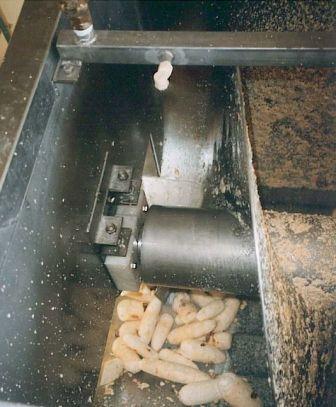

Peeled

cassava leave the peeling machine

|

|

Discharge of the machine

R-OW-130-A

|

|

The peeled product cassava

|

→

Cassava factory in Africa during mounting. Please click on News,

65

|

DORNOW - "radical" roller

peeling machines are able to peel (graded) potatoes, etc. of

very poor quality.

Please also see subsection 1.7.

The

following photos were taken in a potato peeling plant. Please

observe exactly the potato and peeling qualities!

|

25 |

|

26 |

|

27 |

|

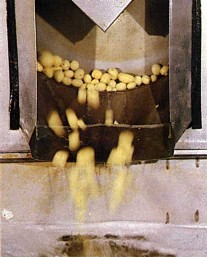

Very poor-quality potatoes before

peeling, graded by commercial potato sorting plants.

|

|

After the first, or partially

after the second peeling procedure, sorted / blemished

potatoes are again processed by the above-mentioned machine.

|

|

The finished product,

made from

worst-quality raw produce.

|

32 |

|

33 |

|

34 |

Beetroot

(red beet), cooked or uncooked, can be peeled

exceedingly good with the roller peeling machines of

the

R-OW series. |

| |

|

For more photos of peeled

products:

please see above or click on the button "Peeled

products" in the green links

on the left hand side.

Machines of the R-OW-series with peeling rollers

approx. 3 m in length

(0151 ff., 0160):

|

1.1.1

|

R-OW-Mini-A

|

Inner

diameter 500 mm, smaller capacity

|

Art.-no.

0160

|

|

1.1.2

|

R-OW- 70-A

|

Inner

diameter 700 mm, small to medium capacity

|

Art.-no.

0151

|

|

1.1.3

|

R-OW- 90-A

|

Inner

diameter 900 mm, small to medium capacity

|

Art.-no.

0152

|

|

1.1.4

|

R-OW-110-A

|

Inner

diameter 1100 mm, medium to large capacity

|

Art.-no.

0153

|

|

1.1.5

|

R-OW-130-A

|

Inner

diameter 1300 mm, large capacity

|

Art.-no.

0154

|

|

1.1.6

|

R-OW-150-A

|

Inner

diameter 1500 mm, very large capacity

|

Art.-no.

0155

|

|

1.1.7

|

R-OW-170-A

|

Inner-diameter

1700 mm, very large capacity

|

Art.-no.

0156

|

|

1.1.8

|

R-OW-190-A

|

Inner-diameter

1900 mm, very large capacity

|

Art.-no.

0157

|

|

1.1.9

|

R-OW-220-A

|

Inner-diameter

2200 mm, very large capacity

|

Art.-no.

0158

|

|

1.1.10

|

R-OW-250-A

|

Inner-diameter

2500 mm, very large capacity

|

Art.-no.

0159

|

|

Machines of the R-OW-series with peeling rollers

approx. 4 m in length

(8265 ff.):

|

1.1.11

|

R-OW-Mini-A1

|

Inner

diameter 500 mm

|

Art.-no.

8265

|

|

1.1.12

|

R-OW- 60-A1

|

Inner

diameter 600 mm

|

Art.-no.

8266

|

|

1.1.13

|

R-OW- 90-A 1

|

Inner

diameter 900 mm

|

Art.-no.

8267

|

|

1.1.14

|

R-OW-110-A1

|

Inner

diameter 1100 mm

|

Art.-no.

8268

|

|

1.1.15

|

R-OW-130-A1

|

Inner

diameter 1300 mm

|

Art.-no.

8269

|

|

1.1.16

|

R-OW-150-A1

|

Inner

diameter 1500 mm

|

Art.-no.

8270

|

|

1.1.17

|

R-OW-170-A1

|

Inner-diameter

1700 mm

|

Art.-no.

8271

|

|

1.1.18

|

R-OW-190-A1

|

Inner-diameter

1900 mm

|

Art.-no.

8272

|

|

1.1.19

|

R-OW-220-A1

|

Inner-diameter

2200 mm

|

Art.-no.

8273

|

|

1.1.20

|

R-OW-250-A1

|

Inner-diameter

2500 mm

|

Art.-no.

8274

|

Machines of

the R-OW-series

with peeling rollers approx. 2 m in length, also suitable

as pre-peelers for blade-type peeling machines

(8050ff.):

|

1.1.21

|

R-OW-500-B

|

Inner diameter 500 mm, smaller capacity

|

Art.-no.

8050

|

|

1.1.22

|

R-OW-600-B

|

Inner diameter 600 mm, small

to medium capacity

|

Art.-no.

8051

|

|

1.1.23

|

R-OW-900-B

|

Inner diameter 900 mm, medium

capacity

|

Art.-no.

8052

|

|

Pictures: see

"News", item 24

Further roller peeling

machines

Please see subsections:

Suggestions for further reading:

| -

Q21 |

DORNOW R-OW series

roller peeling machines in the potato chip (UK:

crisps) industry. |

- Q25

|

DORNOW R-OW series

roller peeling machines in the vegetable

processing as well as in the canning (UK: tinning) and frozen

foods industry |

| - Q26

|

DORNOW R-OW-series

roller peeling machines in commercial potato

peeling plants and in the potato processing

industry |

| - Q30

|

Advantages and

disadvantages of carborundum roller peeling

machines, joint lengthwise and operating in

steps |

| - Q58

|

Peeling of

subtropical and tropical fruit and root vegetables

with DORNOW roller peeling machines |

| - Q63

|

What

are the implications of "peeling without water

and waste water" (with mechanical

peeling machines) for in-plant-practice ? |

- Q106

|

Brief description of DORNOW- R-OW series

roller peeling machines, suitable for the potato

and vegetable processing industries, as well as

the fruit / juice industry |

| - Q06 |

Pure-air

peeling in DORNOW peeling machines |

-

Q12

|

DORNOW to build

5th generation roller peeling

machines

Sturdy construction: durability of 20 years and more! |

| -

Q107 |

Drum-type

roller peeling machines, advantages and disadvantages, fields of

application |

| -

Q130 |

Planning

/ design of peeling systems for

tubers and root vegetables - We offer assistance |

| -

Q159 |

DORNOW

"100" series roller peeling machines |

-

Q160

|

Peeling of blemished, poor-quality potatoes graded by sorting

systems in potato-storage facilities by DORNOW RAD

series radical roller peeling machines |

| -

Q157 |

Peeling

questionnaire |

| -

Q104

|

Steam-peeling in small, midium-sized and large industrial

facilities -

Which peeling method is used where ? |

-

Q78

|

Re-peeling

of still blemished steam-peeled potatoes and other

tubers / root vegetables by DORNOW roller peeling

machines |

| -

Q70

|

Usability

of "waste-peel", especially of potato "waste"

peel, from mechanically operating dry peeling

machines |

| - Q29 |

A

new small DORNOW roller peeler, named "R-OW-Mini-A"

was born ! |

| |

|

|

6

6

11

11 12

12 13

13

18

18

28

28 29

29

34

34